How To Repair A Computer Power Supply Cord

Editors Note: Every bit Todd and Joe point out in the comments of this article, this repair is not acceptable by OSHA standards. Expect for an update to this commodity with an OSHA canonical cord repair in the near hereafter.

Contractors can be brutally tough on their tools, and given enough time, information technology's not uncommon for a ability tool cord to get nicked, damaged or even completely severed. Some manufacturers have responded with removable power cords that are like shooting fish in a barrel to supplant, and those accept been met with mixed reviews. Nonetheless, fixing a broken cord isn't difficult, and it's cheaper than buying a new ane. Today's article is going to prove you how to repair a broken power cord, and I sacrificed an old SKIL jigsaw for this demonstration. After I'1000 finished information technology'll look only as skillful every bit before, albeit a little shorter.

Materials

Earlier I get started, hither'southward a list of materials yous'll demand:

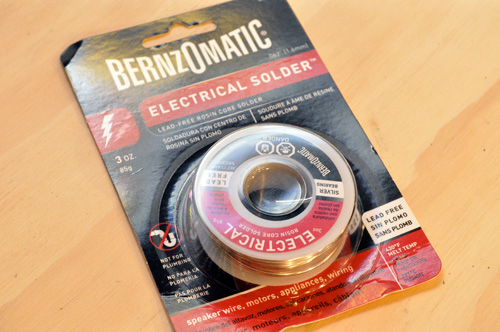

- Electrical solder (not pipe solder)

- Heat compress tubing

- Electric Tape

Tools

- Soldering iron

- Cutting pliers

- Utility knife

- Wire strippers

- Heat gun (or hair dryer)

Step 1: Trim Ends

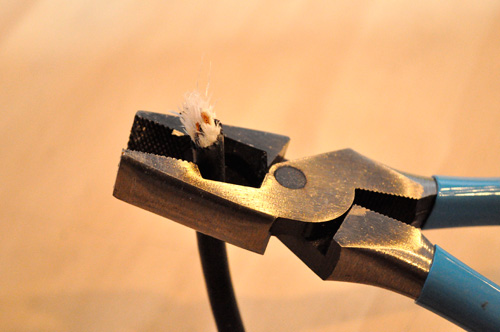

You can run into my miter saw made short work of this power string leaving jagged and frayed edges.

I trimmed both ends with cutting pliers.

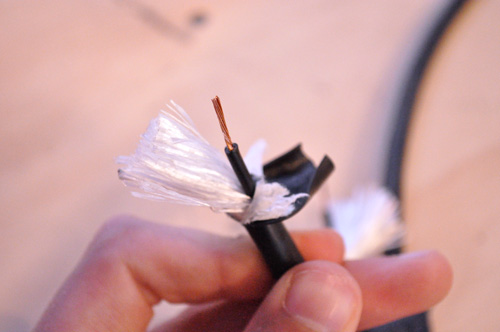

Step 2: Cut Outer Sheathing

Next, I used a utility knife to slice the outer capsule much like cut Romex. I made a lengthwise cut most 2″ long, and peeled back the sheathing.

Pace 3: Strip Wires

I separated out the black and white wires, and used wire strippers to remove a short length of insulation. Odds are that your power string is composed of stranded copper (like mine) so be careful not to cutting any of the strands.

At this signal I set both ends into the alligator clips on my soldering iron station.

Step 4: Twist and Solder

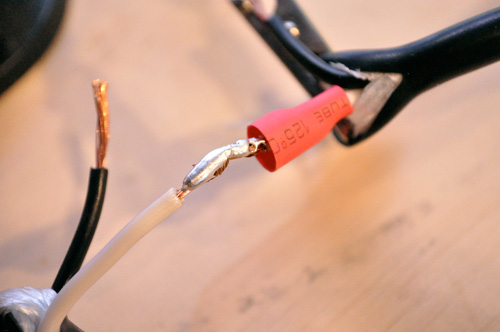

Before connecting the wires, I slipped a oestrus compress tube in place. Heat compress tubes will only constrict so far and then select a tube that is only large plenty to fit over the finished articulation.

I paired the blackness wires and white wires, and wrapped them in-line with the rest of the cord. I used the soldering fe to heat the splice, and when it was hot enough, practical the solder. A expert soldering iron (not like the i I used) will be able to rut the splice quickly and melt the solder without also much trouble. The solder I used melts at 430° F then brand certain your soldering iron tin can get hot enough.

I tried to brand a nice, smooth connection with plenty of solder holding the wires together. Adjacent, I repeated this process for the second pair of wires.

Soldering irons get really hot so exist careful not to fire yourself or the wire insulation. If you make a mistake, trim the ends and offset over.

Pace 5: Rut Shrink Tube

When the soldering was finished and the splices had cooled, I slid the estrus shrink tubes in place, and applied low heat with a oestrus gun until the tubes were tight.

Pace half-dozen: Wrap in Tape

Lastly, I cut back whatever overlapping capsule and removed some of the filler string. Then I wrapped everything with a couple of layers of electrical tape.

In the end, my SKIL jigsaw worked just like before. The cord is completely repaired, and you almost can tell it was ever damaged.

Source: https://www.oneprojectcloser.com/how-to-repair-a-cut-or-damaged-power-cord/

Posted by: sprouselarat1936.blogspot.com

0 Response to "How To Repair A Computer Power Supply Cord"

Post a Comment